How to Identify and Fix Internal Leakage in Directional Control Valves

Directional control valves (DCVs) are vital components in pneumatic and hydraulic structures, controlling the go with the flow of air or fluid to operate actuators, pneumatic cylinders, and other mechanical gadgets. However, one of the most not unusual problems affecting those valves is internal leakage, which can result in decreased performance, multiplied electricity consumption, and machine screw ups. If you are handling inner leakage for your DCV, it’s vital to become aware of the foundation reason and follow the proper fixes to ensure optimal performance.

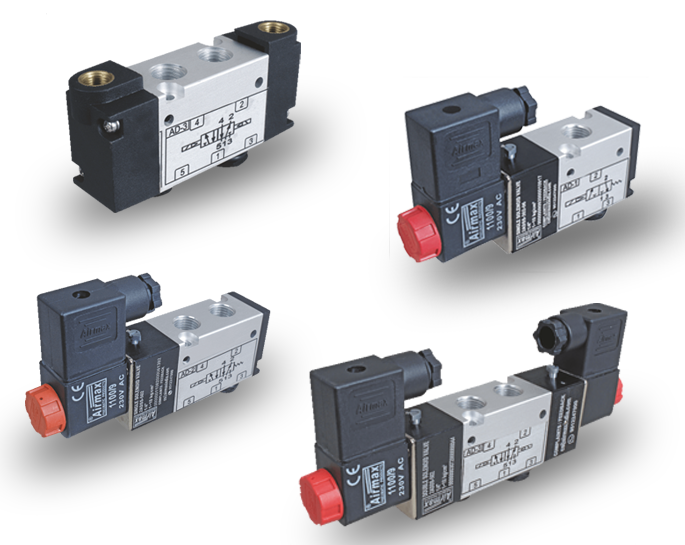

In this blog, we’ll explain to you the way to detect internal leakage in directional control valves and the pleasant techniques to restore those troubles. If you need high-quality directional control valves for your industrial applications, Airmax Pneumatics Ltd. offers premium answers designed for sturdiness and performance.

Understanding Internal Leakage in Directional Control Valves

Internal leakage happens when fluid or air bypasses the valve’s sealing additives, causing unintended motion or stress loss in the This can show up due to numerous reasons, such as tired seals, misalignment, contamination, or broken valve components.

Common Symptoms of Internal Leakage:

- Loss of stress: The device may not preserve the specified stress levels.

- Unintended actuator movement: Cylinders or motors can also reveal themselves in gradual or sudden operation

- Excessive warmth technology: Leakage will increase friction, leading to overheating.

- Increased energy intake: The device compensates for the misplaced strain via the use of extra power.

- Reduced performance and overall performance: Overall productivity declines because of inconsistent valve operation.

Causes of Internal Leakage in Directional Control Valves:

1.} Worn-Out or Damaged Seals:

Seals in directional control valves are designed to prevent leakage with the aid of retaining a tight contact between transferring additives. Over time, these seals can degrade because of:

- Continuous wear and tear

- High-pressure and temperature publicity

- Contamination from dirt and debris

2.} Valve Spool Misalignment:

Misalignment of the spool in the valve body can create gaps, permitting fluid or air to bypass unintended channels. This can be caused by poor set up, mechanical damage, or thermal enlargement.

3.} Contaminants within the System:

Dirt, metallic debris, and other contaminants can cause internal scoring and harm to the valve components. This no longer most effectively speeds up seal wear but additionally disrupts the motion of the spool.

4.} Pressure or Excessive Load:

Operating the valve at pressures past its rated potential can cause inner harm, mainly to leakage. Excessive force on actuators can also place stress on the valve additives, inflicting untimely failure.

5.}Improper Valve Selection:

Using an incorrectly sized or incompatible valve for your utility can result in poor sealing, internal leakage, and inefficient machine performance overall.

How to Fix Internal Leakage in Directional Control Valves

1.} Replace Worn-Out Seals:

- Inspect seals frequently and update them if they appear cracked, hardened, or deformed.

- Use tremendous seals well matched with your operating situations (temperature, stress, and fluid kind).

- Apply lubrication where essential to lessen friction and extend the seal’s life.

2.} Ensure Proper Spool Alignment:

- Check for any misalignment troubles by examining the spool’s movement.

- If misalignment is detected, reposition the spool consistent with manufacturer’s suggestions. If important, replace the spool or re-machine the valve body for proper match.

3.} Clean the Valve and System Components:

- Flush the system to do away with contaminants using easy fluid or air.

- Install remarkable filtration systems to prevent destiny infection.

- Regularly smooth and keep the complete hydraulic or pneumatic circuit.

4.} Monitor Pressure and Load Conditions:

- Always perform the valve within its endorsed strain range.

- If overpressure is detected, install a pressure comfort valve to guard the machine.

- Ensure actuators and masses are well-matched to prevent immoderate pressure on the valve.

5.} Choose the Right Directional Control Valve:

- Select a super directional control valve from a dependable producer like Airmax Pneumatics Ltd.

- Ensure the valve matches your gadget’s flow rate, pressure, and environmental conditions.

- Consult with experts to decide the appropriate valve type for your precise application.

Why Choose Airmax Pneumatics Ltd. For Directional Control Valves?

At Airmax Pneumatics Ltd, we provide top rate-exceptional directional control valves designed for high efficiency, sturdiness, and performance. Our valves are constructed to withstand intense conditions even as minimizing internal leakage and ensuring easy operation.

Key Features of Our Directional Control Valves:

- Leak-proof layout: Precision engineering ensures minimal internal leakage.

- High-overall performance sealing era: Our advanced seals enhance durability.

- Robust creation made from top-class substances for long-lasting overall performance.

- Efficient flow control: Designed to optimize device efficiency and reduce power intake.

- Customizable solutions: Available in diverse configurations to fulfill your particular necessities.

If you are experiencing leakage troubles for your directional control valves, making an investment in a brilliant alternative from Airmax Pneumatics Ltd. is a clever decision. Our valves are designed to supply precision, reliability, and performance, making sure that your operations run easily without high-priced downtime.

Conclusion

Internal leakage in directional control valves can cause sizable overall performance troubles, including stress loss, inefficient operation, and increased electricity prices. By identifying the causes, which include worn seals, misalignment, contamination, or excessive pressure, you may take corrective measures to restore the most reliable capability.

Regular upkeep, proper installation, and deciding on amazing valves like those from Airmax Pneumatics Ltd. will help save you from leakage issues and enhance the toughness of your application. Don’t permit internal leakage to disrupt your operations.

Looking for dependable, leak-proof directional control valves? Contact us today & enjoy advanced first-rate performance!