Pneumatic Solutions for Painting and Coating Industries

In the painting and coating industry, precision and consistency aren’t just good to have, they’re important. Whether it’s an automotive assembly line or a furniture manufacturing plant, the quality of the finish defines the product’s value and customer satisfaction. Behind that flawless conclusion Pneumatic systems stand as an important factor.

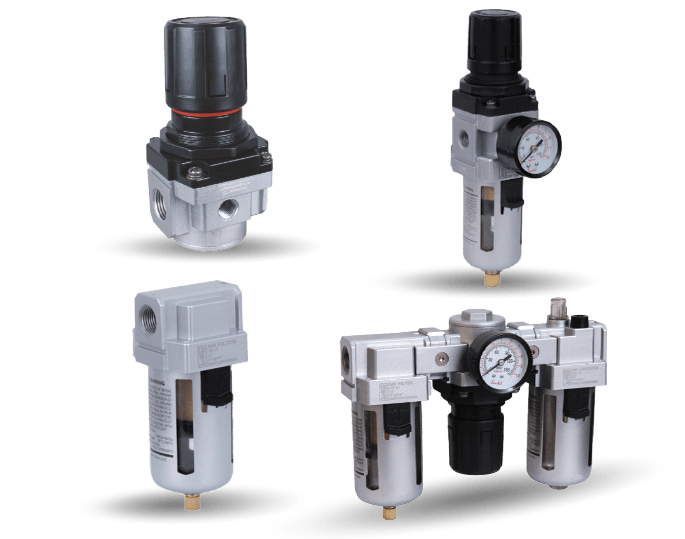

At Airmax Pneumatics, we specialize in delivering innovative pneumatic solutions from air preparation units to FRL (Filter Regulator Lubricator) units and reliable pneumatic accessories manufactured specifically to fulfill the demands of the painting and coating industry.

Let’s learn how the right pneumatic components can revolutionize your painting process.

Pneumatics Matter in Painting and Coating

Compressed air is the vitality of spray painting systems, however, raw compressed air isn’t clean. It’s often full of moisture, oil particles, and debris. If not handled, this can result in flaws such as blotching, fisheyes, irregular coats, and paint contamination, which no quality-conscious manufacturer can afford.

This is where air preparation systems step in, ensuring that the air feeding your spray gun is dry, clean, and regulated. The result? A smooth, flawless finish with fewer reworks and maximum material efficiency.

Air Preparation Units: The Foundation of Flawless Painting

A well-prepared air supply makes all the difference. Our Air preparation units are designed to condition compressed air to meet the exact needs of spray painting systems.

Key Features:

- High filtration efficiency to remove dirt, moisture, and oil

- Pressure regulation for consistent spray patterns

- Modular design for ease of installation and maintenance

- Durable construction suitable for industrial environments

Airmax Pneumatics offers modular air preparation units that include air filters, regulators, and lubricators, ensuring optimal air quality and performance. With these units in place, paint application becomes more consistent, equipment life is extended, and downtime is significantly reduced.

FRL Units:

Every professional spray setup needs a reliable FRL unit, a compact combination of a filter, regulator, and lubricator that maintains air quality, pressure, and tool lubrication.

Benefits of Our FRL Units for Painting Systems:

Clean Air Delivery: Filters out solid particles, oil aerosols, and moisture to prevent clogging and contamination in spray guns.

Steady Air Pressure: Regulators maintain consistent airflow, ensuring smooth and even paint application.

Tool Longevity: Lubricators extend the life of pneumatic tools by ensuring proper lubrication with every cycle.

At Airmax Pneumatics, our FRL units are built with premium-grade components and are available in multiple sizes and configurations to suit both manual and automated painting setups.

Pneumatic Accessories: The Silent Champion

Behind every smooth-running pneumatic system are the accessories that bring everything together, fittings, tubing, connectors, silencers, quick couplers, and more.

At Airmax Pneumatics, we provide a comprehensive range of pneumatic accessories that offer:

- Leak-proof performance for consistent air delivery

- High durability under industrial conditions

- Easy integration with existing systems

- Corrosion resistance to withstand exposure to paint and solvents

With the right accessories in place, your painting system becomes more efficient, reliable, and easier to maintain.

Common Challenges in Painting Applications and How Airmax Helps

Moisture and Oil in Air Lines:

Even a tiny drop of oil or water can ruin an entire paint job. Our high-efficiency filters and dryers ensure air purity, keeping your finishes perfect.

Inconsistent Spray Patterns:

This is often due to fluctuating air pressure. Our precision regulators stabilize pressure, delivering a uniform spray every time.

Frequent Tool Breakdowns:

Lack of lubrication can wear out your pneumatic tools. Our lubricators ensure each tool is properly oiled without overdoing it, keeping your operations smooth and cost-effective.

Downtime Due to Maintenance:

Our modular units are designed for quick servicing and easy replacement, minimizing downtime and ensuring maximum productivity.

Applications in the Painting and Coating Industry:

Airmax Pneumatics products are widely used in:

- Automotive painting booths

- Furniture manufacturing

- Metal fabrication units

- Appliance and consumer goods finishing

- Powder coating plants

- Industrial machinery painting lines

Beyond air preparation, the precision of your coating process is often maintained by the synchronized movement of a pneumatic cylinder. In high-speed industrial lines, these pneumatic cylinders manage the exact positioning of spray guns and conveyor gates, ensuring uniform material application. By utilizing cylinders with robust, corrosion-resistant seals, manufacturers can prevent contamination and maintain the consistent mechanical actuation required for a flawless finish across all production cycles.

Whether it’s high-precision robotic spray systems or manual spray guns, our pneumatic solutions are manufactured for compatibility, efficiency, and durability.

If you want to learn about boosting powder coating efficiency then click on the link.

Why Choose Airmax Pneumatics?

With decades of expertise in pneumatic technology, Airmax Pneumatics is committed to supporting manufacturing excellence through reliable, performance-driven products.

Our solutions are trusted by OEMs, system integrators, and manufacturers across India and beyond. We help companies optimize performance, reduce operating costs, and ensure high-quality output in their painting and coating processes.

Let’s Paint a Brighter Future Together

When it comes to painting and coating, don’t let subpar air quality or unreliable components tarnish your final product. At Airmax Pneumatics, we’re here to elevate your operations with industry-leading air preparation units, FRL units, and pneumatic accessories that deliver lasting value.

If you’re looking to enhance your spray painting systems, reduce maintenance costs, and deliver a superior finish every time, get in touch with us today. Let’s build a cleaner, smoother, more efficient coating process together.