Single vs. Double Pilot Valves: Which is Right for Pneumatic System?

When you’re running a pneumatic system, choosing the right type of valve can make or break your operation. Whether you’re powering machinery in packaging, manufacturing, or assembly lines, the efficiency and safety of your setup depend heavily on how your air flows and how it’s controlled.

Single and double pilot valves are two common types of pneumatic control valves that play a critical role in automation. But which one should you choose for your application?

Let’s explore the function, operation, applications, and examples of each, so you can make a well-informed decision. At Airmax Pneumatics Ltd, we’re committed to delivering high-performance pilot valves tailored to your specific needs. With decades of industry experience and precision-engineered designs, we help industries across India and the globe optimize their pneumatic systems for safety, performance, and reliability.

What is a Pilot Valve in a Pneumatic System?

Before diving into the comparison, it’s essential to understand what a pilot valve does. A pilot valve uses a smaller control signal (often air pressure) to control a larger main valve or device. In simple terms, it’s a valve that controls another valve. This pilot mechanism reduces the need for larger actuation forces and enables remote, automatic, and highly responsive control of pneumatic components.

At Airmax Pneumatics Ltd, our pilot valves are designed for long life, fast response, and minimal leakage, making them ideal for demanding industrial environments.

What is a Single-Pilot Valve?

Function and Operation:

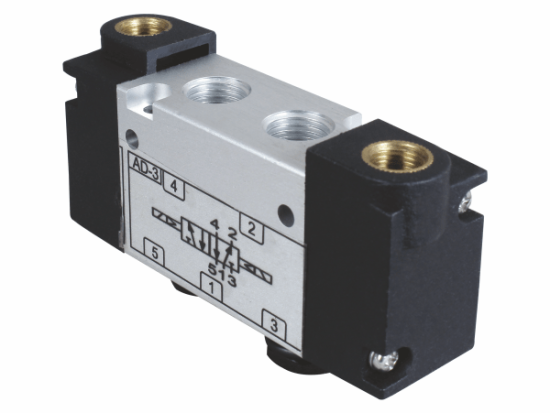

A single pilot valve is a type of directional control valve that uses one pilot air signal to shift the valve from its default position. Once the signal is removed, a spring return mechanism brings the valve back to its original position.

- Default State: Spring-return position (fail-safe)

- Shift Mechanism: One pneumatic signal

- Reset Mechanism: Spring automatically resets the valve

Think of it as a momentary push-button. Once pushed (actuated), it performs its task and resets itself automatically when the input is gone.

Common Features of Single-Pilot Valves:

- Usually found in 3/2-way single pilot valve or 5/2-way single pilot valve configurations

- Simple and cost-effective

- Provides automatic return to a safe/default state

- Ideal for processes that don’t need to maintain a position indefinitely

Applications of Single-Pilot Valves:

- Emergency air dump systems

- Presses and cylinders requiring spring return

- Packaging lines with intermittent operations

- General-purpose automation machinery

Real-World Example:

In a packaging conveyor, a pneumatic cylinder may be used to divert products into different chutes. A single pilot valve actuates the cylinder when a sensor detects the product. Once the product has been diverted, the signal stops and the valve springs back, returning the cylinder to its original position without any additional input.

At Airmax Pneumatics Ltd, our single pilot valves are known for their compact design, high flow efficiency, and robust construction. They are a preferred choice for packaging, bottling, and small automation setups.

What is a Double Pilot Valve?

Function and Operation:

A double pilot valve, often called a memory valve, uses two pilot signals, one for each direction· When either signal is applied, the valve shifts and remains in that position until the opposite signal is received.

Unlike single pilot valves, double pilot valves do not use a spring. The valve “remembers” the last command, which is why it’s also known as a bistable or latching valve.

Default State: None

Shift Mechanism: One pilot signal to change position

Retention: Maintains position until the opposite signal is applied

Common Features of Double Pilot Valves:

- Typically 5/2-way double pilot valve configurations

- Perfect for maintaining actuator positions

- Ensures that the valve does not reset upon power loss

- Ideal for complex automation systems

Applications of Double Pilot Valves:

- Pneumatic presses

- Robotic arms and actuators requiring memory positioning

- Automated assembly lines

- Situations requiring position retention during shutdowns

Real-World Example:

Imagine an automated assembly press in an automobile plant. A double pilot valve operates the press to extend and hold until the part is assembled. Even if there’s a brief drop in control signal or air pressure, the press will hold its position. It will only retract when the opposite pilot signal is applied, providing safety, consistency, and reliability.

Airmax Pneumatics Ltd offers a wide range of double pilot valves built to withstand high cycles, temperature extremes, and rough environments, ensuring long-lasting performance in your facility.

Key Differences Between Single and Double Pilot Valves:

Here’s a quick comparison to help you differentiate between the two:

| Feature | Single Pilot Valve | Double Pilot Valve |

| Number of Pilot Signals | One | Two |

| Return Mechanism | Spring Return | Latching Mechanism no spring) |

| Position Relation | No (return to default) | Yes (holds last position until changed) |

| Safety Behavior | Returns to fail-safe position on signal loss | May hold an unsafe position on signal loss |

| Control Logic | Simple | Slightly more complex |

| Common Use Cases | Inherent motion, safety reset | Continuous motion, memory functions |

| Cost and Complexity | Lower | Slightly higher |

| Our Valve Models | 3/2, Spring return | 5/2 memory type |

The decision between a single or double pilot configuration ultimately governs the movement profile of your pneumatic cylinder. While a single pilot valve is ideal for cylinders requiring a fail-safe return to the home position, a double pilot ‘memory’ valve is essential for maintaining a specific stroke position during complex assembly tasks. Selecting the correct valve logic ensures that your cylinder operates with the exact timing and safety behavior required for high-speed industrial automation.

How to Choose the Right Pilot Valve for Your System:

Making the right choice is not just about specs, it’s about understanding your

system behavior, safety requirements, and operational efficiency.

Here’s what you should consider:

Safety Requirements:

If your system requires a fail-safe return (Eg., in case of emergency or power failure), choose a single pilot valve. Its spring-return action ensures the actuator returns to a neutral or safe position.

Automation Logic:

If you need the actuator to maintain its position until a deliberate change is made (Eg., pressing, clamping), then a double pilot valve is the best choice. It offers a memory function essential for complex or semi-automatic operations.

System Complexity:

Simpler systems benefit from the straightforward nature of single pilot valves, while double pilot valves fit better in advanced automation setups with multiple sensors and feedback loops.

Energy Consumption:

Double pilot valves may offer better energy efficiency in systems where holding a position doesn’t require constant actuation, as the valve doesn’t reset and therefore doesn’t need continuous pressure.

Why Airmax Pneumatics Ltd is Your Ideal Pilot Valve Supplier:

At Airmax Pneumatics Ltd, we’re more than just a valve manufacturer — we’re your partner in automation excellence.

Industry-Leading Expertise:

With over 20 years of experience, our team understands the unique challenges of industries like textiles, pharmaceuticals, oil & gas, food processing, and heavy machinery.

Durable Construction:

Our pilot valves are built from high-grade materials like aluminum, stainless steel, and brass. They withstand harsh industrial environments while delivering consistent performance.

Tailored Solutions:

Need a custom valve configuration? Our engineers work directly with your technical team to provide application-specific solutions that boost performance and reduce downtime.

Pan-India Support:

From Ahmedabad to Bengaluru, Airmax Pneumatics Ltd ensures timely deliveries, local support, and prompt customer service for all your pneumatic needs.

Industries We Serve:

Our pilot valves are used in a wide range of industries, including:

- Automobile manufacturing

- FMCG packaging plants

- Textile mills

- Petrochemical refineries

- Pharmaceutical factories

- Plastic molding and extrusion units

- Food and beverage plant

If you operate machinery that needs directional air control, Airmax Pneumatics Ltd has the right valve for you.

Conclusion: Let’s Find the Right Valve Together

Choosing between a single or double pilot valve isn’t just about specs, it’s about choosing control, safety, efficiency, and peace of mind.

- Go for a Single Pilot Valve when you need simple control with automatic reset.

- Choose a Double Pilot Valve when your system requires memory control and latching functionality.

No matter your choice, Airmax Pneumatics Ltd. provides the best pilot valves in India, trusted by engineers and plant managers for their durability, performance, and engineering precision.